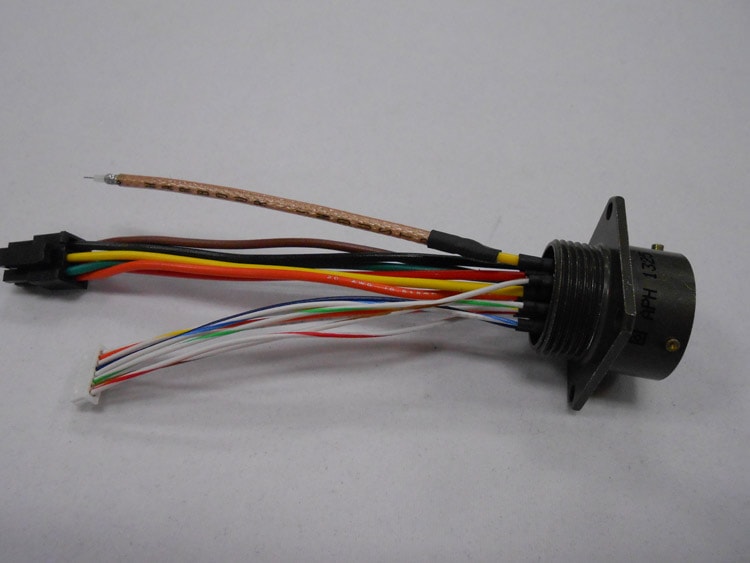

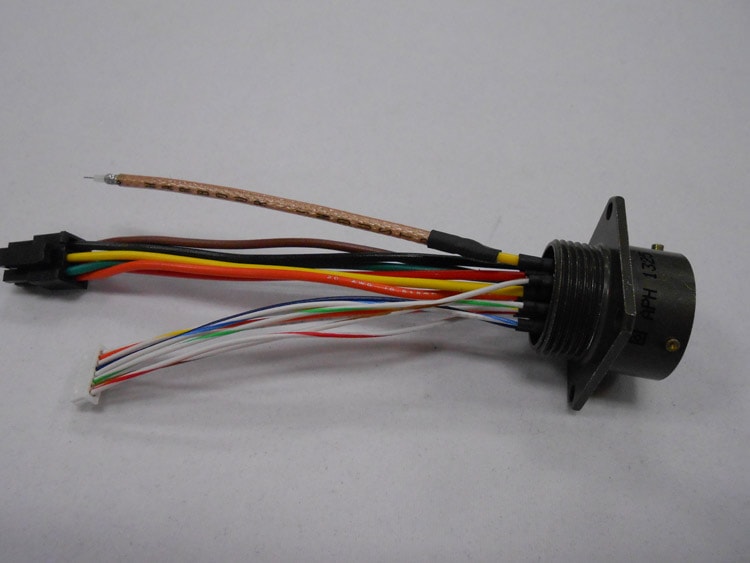

Quality Cable Source, Inc. brings a broad spectrum of expertise and equipment to the manufacture of sub-assembly cables. Contact us today to find out how they can work with you to support your manufacturing operations.

Quality Cable Source, Inc. brings a broad spectrum of expertise and equipment to the manufacture of sub-assembly cables. Contact us today to find out how they can work with you to support your manufacturing operations.